Guide to Using API594 Dual Plate Check Valve 150LB 40 Inch A216 WCB in Oil and Gas Applications

The API594 dual plate check valve is important in oil and gas systems. This check valve stops backflow and keeps equipment safe from harm. Operators pick the 150LB, 40 Inch, and A216 WCB types for many reasons:

The 150LB rating works well for medium pressure pipes. It helps keep things safe and saves money.

The 40 Inch size lets lots of fluid move through. It lowers pressure loss in the system.

A216 WCB carbon steel is strong and fights rust. This makes the valve last longer in tough places. These features help the check valve follow strict api rules. They also make fluid control work well and stay reliable.

Key Takeaways

The API594 dual plate check valve stops flow from going backward. It keeps equipment safe in oil and gas systems. Its small size helps it fit in tight spaces. The wafer-type connection makes it easy to put in pipelines. Strong A216 WCB carbon steel makes the valve tough. Fast-closing springs help it last longer and stop damage. The valve works in many temperatures and pressures. It fits most oil and gas pipelines. Picking the right valve size is important for safety. You also need the right pressure class and material for good use.

Overview

What Is a Check Valve

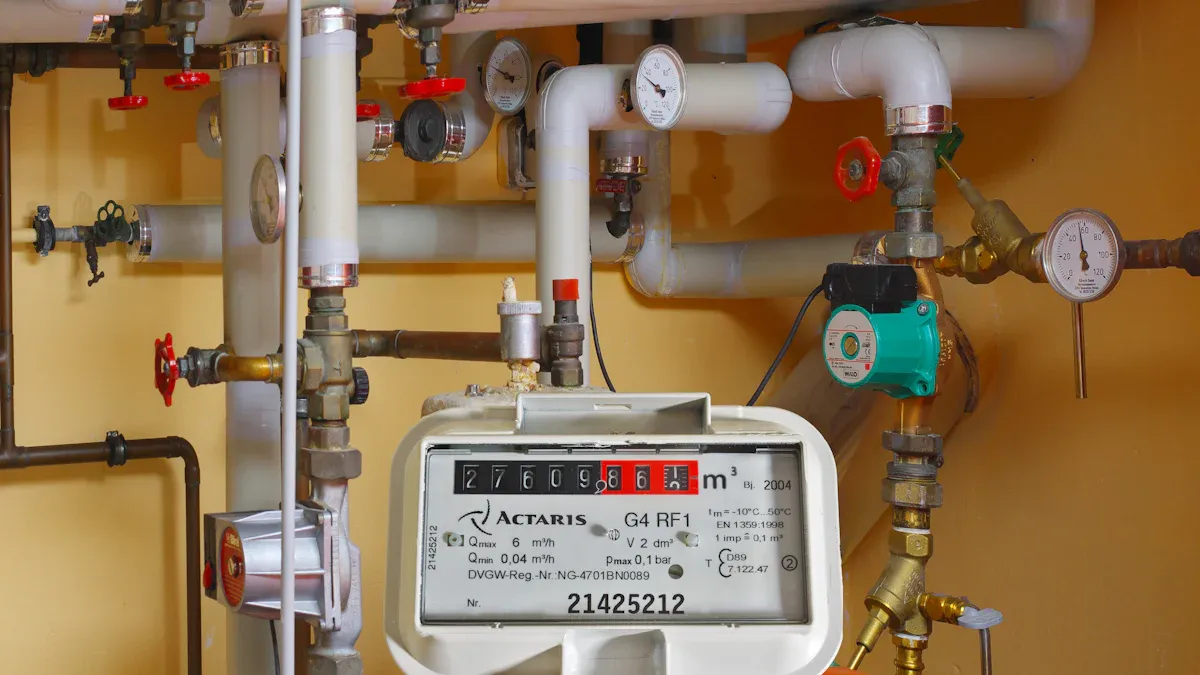

A check valve lets fluid move one way. It stops fluid from going back. This helps protect pumps and pipes from getting damaged. Engineers use different check valves in big systems. Each kind works best for certain jobs.

The table below shows how check valves are different:

Check Valve Type | Design and Function | Advantages | Limitations | Common Applications |

|---|---|---|---|---|

Swing Check Valve | Hinged disc swings open/closed with flow | Low pressure drop, good for slow flow | Not good for pulsing flow, water hammer can happen | Water, HVAC, oil & gas pipelines |

Ball Check Valve | Spherical ball blocks reverse flow | Simple, easy to care for, handles solids | More pressure drop, not for low pressure | Pump discharge, slurry, food processing |

Lift Check Valve | Disc moves up and down to open/close | Good for high pressure, works both ways | Not for dirty fluids, needs to be straight | Steam, high-pressure water, chemical plants |

Diaphragm Check Valve | Soft diaphragm bends to open/close | Clean, keeps things safe from germs | Not for high pressure, wears out with rough fluids | Pharmaceutical, food, chemical dosing |

Wafer Check Valve | Thin, discs swing open/close | Small, light, easy to put in | Not for thick fluids, fits some pipe sizes | Power plants, HVAC, industrial piping |

Swing check valves are still used a lot in oil and gas. But wafer check valves, like the dual plate type, are smaller and fit new systems better.

API 594 Check Valve Basics

The api 594 check valve is known for strong rules on how it is made. API 594 has two main dual plate check valve types: Type A and Type B. Type A is short and fits in tight spaces. Type B is longer and stronger for hard jobs.

The dual plate check valve has two plates that move on a hinge. The plates open when fluid goes forward. They close fast to stop fluid from going back. This design makes less noise and stops water hammer. It is also easy to put in and fix.

Engineers pick the api 594 check valve because it seals well and meets api rules. There are wafer-style, lug-style, and full-bodied dual plate check valves. Wafer-style saves space and fits between flanges. Lug-style lets you take off pipes for fixing. Full-bodied is very strong for high pressure.

The api 594 check valve is made to stop fluid from going backward in important places. Unlike other api rules, api 594 is just for check valves. It looks at how strong and tight they are. This helps keep oil and gas, power plants, and factories safe and working well.

Design

Dual Plate Check Valve Mechanism

The double plate check valve is special in fluid control. Engineers made it with two half-circle plates on a hinge. When fluid moves forward, both plates swing open. If the flow stops or goes backward, springs snap the plates shut. This stops fluid from going the wrong way and keeps the system safe.

Some good things about dual plate check valves are:

The spring helps the plates close fast, so water hammer and pressure jumps are less likely.

The flow path is smooth, so there is less turbulence and pressure loss. This saves energy and helps parts last longer.

The valve is small and light, so it fits in tight spots.

It seals tightly and does not slam shut, so it is quiet and works well.

You can put these valves in pipes that go sideways or up and down.

There are not many moving parts, so it needs less fixing and lasts longer.

The double plate check valve reacts fast when flow changes. Its no slam feature makes sure it shuts smoothly and protects pipes from shocks. This design is better than old swing check valves because it is faster, works better, and is more reliable.

Wafer-Type Connection

The wafer-type connection makes putting in a double plate check valve easy. This design lets the valve fit between two pipe flanges. Long bolts go through the flanges and the valve to hold it tight. There are no big flanges or screw holes, so the valve is lighter and smaller.

This way of connecting has some good points:

It takes up less space, so it is good for crowded pipes.

There are fewer parts, so it is faster and cheaper to put in.

It is easy to mount. You just put the valve between flanges and tighten the bolts.

Note: Wafer-type connections work best in the middle of pipes, not at the ends where you take things apart a lot.

The double plate check valve with a wafer-type connection is a smart choice for engineers who want fluid control that is easy, reliable, and saves money.

Features

A216 WCB Material

Engineers use ASTM A216 WCB carbon steel for the valve body and disc. This steel is strong and does not get damaged by many chemicals. Each batch gets tested to make sure it is good. The steel is heated up to 1200°C to make it tougher. Special tests like DPT, MT, UT, and RT check if the metal is solid and safe.

ASTM A216 WCB carbon steel does not rust or wear out fast.

The steel helps the valve seal tight, so leaks do not happen.

Quality checks use special tools to test the steel’s strength.

The design is small and uses springs, which work well with strong steel.

These things make the dual plate check valve good for hard jobs in oil and gas. The steel meets API 594 and API 6D rules, so it is safe and works well.

Temperature and Pressure Range

The api 594 check valve works in hot and cold places. It can handle temperatures from -29°C to 300°C. This means it works with many fluids in factories. The 150LB pressure rating fits most oil and gas pipes.

Specification | Details |

|---|---|

Valve Type | API 594 Dual Plate Check Valve |

Body Material | ASTM A216 WCB |

Size | 40 Inch |

Pressure Class | 150 LB |

Working Temperature | -29°C to +300°C |

End Connection | Wafer-Type |

Design Standard | API 594 |

The valve has a big opening, so lots of fluid can move through. This helps save energy and lowers costs. The valve’s ratings match what most factories need.

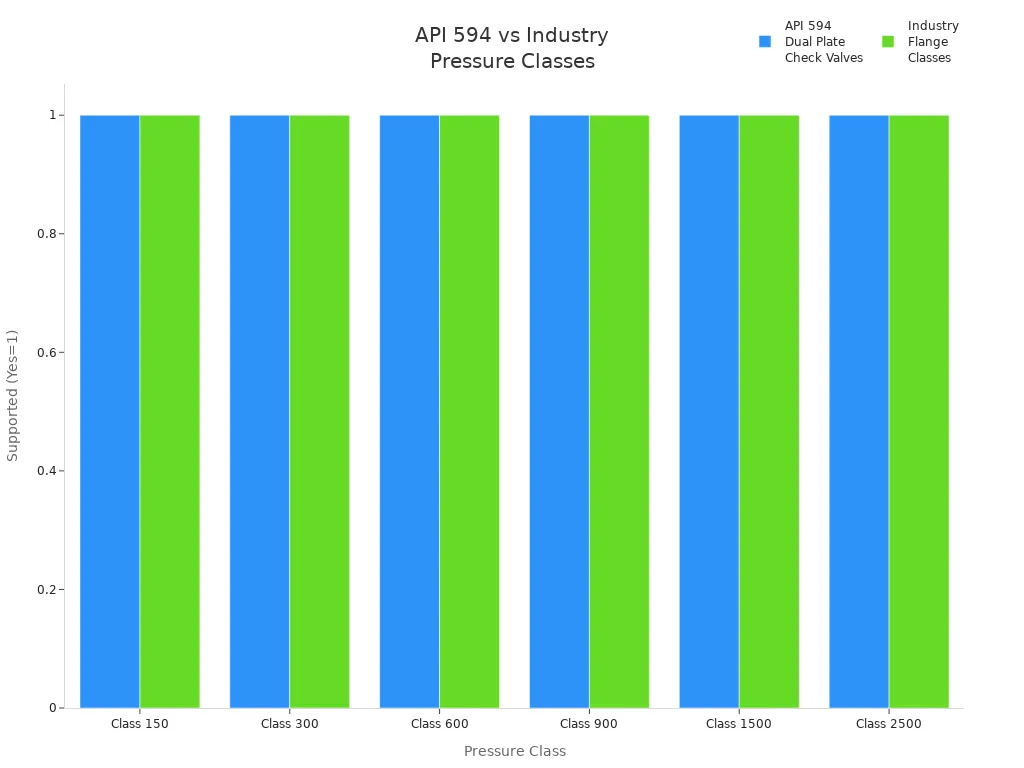

The chart shows API 594 dual plate check valves work from 150LB to 2500LB. This matches the pressure classes used in many factories. The valve is good for oil and gas, chemical plants, and water treatment.

Compliance with API and Industry Standards

The dual plate check valve follows strict world rules. These rules help keep people and equipment safe.

Standard Category | Applicable Standards and Details |

|---|---|

Design Standards | API 6D, API 594 |

Testing Standards | API 6D, API 598 |

Flange End Standards | ASME B16.5 (NPS 2-24), ASME B16.47 Series A (NPS 26+), Series B on request |

Face-to-Face Dimensions | API 6D, ASME B16.10 |

Material Standards | ASTM specifications for carbon steel, stainless steel, alloy steel, and special alloys |

ASME B16.34 makes sure valves are safe for pressure and heat.

NACE MR-01-75 says what steel to use for sour gas, so it does not crack.

Following these rules means the valve is safe in tough places.

The wafer-type connection makes putting in the valve easy. Engineers put the valve between flanges and bolt it in place. This saves space and time. The valve is small and light, so it fits in tight spots.

These features help workers keep oil and gas systems safe and running well. The valve meets API, ASME, and NACE rules, so it lasts long and works right.

Applications

Oil and Gas Industry Use

The dual plate check valve is very important in oil and gas. Engineers use this valve to keep equipment safe. It helps control the way fluid moves in pipelines. Here are some main ways people use this valve:

Oil and gas processing: Operators put these valves in systems from wells under the sea. The valves help separate oil, gas, and water.

Water treatment and injection: Facilities treat water from separation or seawater. The valve makes sure water is safe before it is thrown away or put back in.

LNG processes: The valve helps cool gas to very cold temperatures. This turns gas into liquid for easy storage and moving.

These uses give many good things:

Fast closing with Nimonic springs stops water hammer. This keeps pipelines safer.

The valve is small and light. This makes it cheaper and easier to put in and fix.

The valve lets fluid move with little pressure loss. This saves energy.

Materials that fight rust help the valve last longer in tough places.

Following API 594 and other rules means the valve works well in all parts of oil and gas.

Operators pick this valve because it stops backflow. It protects pumps and compressors. It also lowers fixing costs. The valve can handle oil, gas, steam, water, and chemicals. This makes it a smart choice for many pipelines.

Other Industrial Applications

Many industries use the dual plate check valve. It helps control fluid and keeps equipment safe. The table below shows where the valve is used and what fluids it handles:

Industry | Types of Fluids Handled |

|---|---|

Offshore Engineering | Seawater (used in seawater pipeline systems) |

Chemical Industry | Corrosive media such as acids, alkalis, and salts |

Water Treatment Systems | Water (to prevent backflow and protect pumps/pipelines) |

Petroleum and Natural Gas | Petroleum and natural gas (for safe pipeline operation) |

Industrial Fluid Systems | Various fluids including cooling water and steam |

These industries like the valve because it works well and handles many fluids. Using it in pipelines helps keep systems safe and working right.

Select the Right API 594 Check Valve

Sizing and Pressure Considerations

Engineers need to pick the right size and pressure class for an api 594 check valve in oil and gas systems. The valve size should match the pipe size. This helps fluid move easily and stops blockages. A 40-inch valve lets a lot of fluid pass with little pressure loss.

Choosing the pressure class is very important for safety. The pressure class, like 150LB or 300LB, shows the highest pressure the valve can handle at certain temperatures. In oil and gas work, the pressure class must be as strong as the flanges and other pipe parts. If the flange is weaker, it sets the highest pressure for the whole system. Matching the valve’s pressure class to the system keeps things safe and stops leaks.

The table below shows common pressure classes and where they are used:

Pressure Class | Typical Max Pressure (psi) | Common Applications |

|---|---|---|

150LB | 285 | General oil and gas pipelines |

300LB | 740 | Medium-pressure process systems |

600LB | 1480 | High-pressure refinery and offshore |

900LB+ | 2220+ | Subsea, critical service, high temp |

1500LB-2500LB | 3705-6170 | Extreme pressure, specialized plants |

Note: API flanges can handle more pressure than ASME/ANSI flanges of the same size. For example, an ASME/ANSI weld neck flange rated at 600 psi matches an API 6A flange rated at 2000 psi. This means API flanges and valves are better for strong refinery and subsea jobs.

STV Valve Technology Group makes dual plate check valves from 2 inches to 60 inches and pressure classes from 150LB to 2500LB. This gives engineers many choices for any oil and gas project, from regular pipes to high-pressure and high-temperature places.

Material and Fluid Compatibility

Picking the right material for a check valve is just as important as choosing the size and pressure class. The valve material must handle the fluid’s properties and the place where it works.

Some things to think about are:

How corrosive the fluid is, its temperature, pressure, thickness, and if it has particles.

If stuff can build up inside the valve.

All the working and safety conditions, like very hot or cold temperatures and high pressure.

Outside things like wet weather, rain, desert heat, or being near the sea.

If the valve needs to fight rust to last long and work safely.

Common valve materials are:

Carbon steel (like ASTM A216 WCB): Good for fluids that do not cause rust, like oil, water, and natural gas.

Stainless steel or special alloys: Best for fluids that cause rust, acids, or sour gas.

Bronze and cast iron: Used for water or low-pressure jobs.

Tip: Always pick a valve material that matches the fluid and where it will be used. For example, stainless steel does not rust in chemical plants, but carbon steel works well in regular oil and gas pipes.

Choosing the right material stops rust, keeps fluids clean, and helps the valve last longer. It also makes sure the valve meets all api and industry safety rules. By thinking about these things, engineers can pick the best api 594 check valve for any oil and gas job.

Installation

Preparation and Mounting

Putting in the API594 dual plate check valve the right way is important. This helps the valve work well and last a long time. Workers should look for the flow direction arrow on the valve before putting it in. If the valve goes in the wrong way, it can leak or let fluid go backward.

Before starting, workers need to clean the pipe. They must take out dirt, welding bits, or metal pieces. This keeps the valve from getting stuck and protects the seals. Using the right tools to check the flanges helps stop leaks and broken bolts. All bolts should turn easily by hand. This shows the valve is lined up right.

The table below shows some common mistakes, what can go wrong, and how to stop problems:

Common Error | Consequence | How to Avoid |

|---|---|---|

Wrong flow direction | Valve disc fails, backflow occurs | Follow flow arrow on valve body |

Dirty pipeline | Valve core sticks, leaks | Clean pipeline before installation |

Incorrect angle or orientation | Valve does not close properly | Install in correct orientation for the pipeline |

Valve too close to pump outlet | Water hammer, valve or pipeline damage | Maintain distance from pumps |

Lack of support for large valves | Leakage or rupture | Provide proper support and anchoring |

Big valves need extra support so they do not shake or move. This stops leaks and breaks. Putting in seals and gaskets the right way helps keep leaks away. After putting in the valve, workers should check that the plates move easily and the valve works well.

Maintenance Tips

Checking the dual plate check valve often keeps it working well. Workers should look at the valve two times a year or as the maker says. When checking, they need to look for worn parts, rust, or dirt inside. Cleaning out dirt or sludge helps the valve work its best.

If seals, springs, or discs look worn out, workers should change them right away. After fixing, they should test the valve with water or air to make sure it works and seals tight. Workers must always let out pressure and wear safety gear when fixing the valve.

Doing these steps helps the valve last longer and keeps oil and gas systems safe and working right.

Sourcing and Support

Manufacturer and Delivery

STV Valve Technology Group is a trusted maker of API594 dual plate check valves. The company is in Wenzhou, China. It can make up to 6,000 tons of valves each year. This means customers get their orders on time, even if they need a lot or need them fast.

If someone orders a 40 Inch, 150LB API594 dual plate check valve, the wait time is like other big companies. Most companies take 15 to 30 days to make a sample, depending on what changes are needed. For big orders, it usually takes 30 to 60 days to deliver. STV Valve Technology Group answers questions fast, often in just two hours. This helps orders move quickly. Because of this, many people pick this company for oil and gas jobs all over the world.

Tip: Talk to the manufacturer early. This helps make sure all needs for the product and delivery are met.

Packaging and Payment Options

STV Valve Technology Group uses strong packaging to keep big valves safe when shipping far away. They use tough wooden boxes or crates, as API 594 section 9.3 says, to stop the valves from moving or getting hurt. Each valve gets covers made of wood, plastic, or metal to protect the openings and sealing parts. If the buyer does not say how to pack the valves, the company still packs them safely, sometimes using pallets or putting crates together.

For paying, STV Valve Technology Group gives many choices. Customers can pay by L/C (Letter of Credit), T/T (Telegraphic Transfer), Western Union, or MoneyGram. These ways make paying safe and easy for both small and big orders.

Payment Method | Description |

|---|---|

L/C | Letter of Credit |

T/T | Telegraphic Transfer |

Western Union | International Money Transfer |

MoneyGram | International Money Transfer |

These ways of getting and supporting help customers get good valves safely and on time. The payment choices also fit what customers need.

The API594 dual plate check valve meets many safety rules. It works well in oil and gas systems. Some good things about this valve are:

The spring helps the disc close fast and control flow.

Strong materials help stop rust and damage.

To pick the best check valve, engineers should:

Check that the valve has the right safety papers.

Ask experts for advice to get the best choice.

If you need help or want to buy a valve, talk to a trusted manufacturer.

FAQ

What does "150LB" mean for a check valve?

The "150LB" rating tells how much pressure the valve can take. It means the valve works up to 285 psi when it is not too hot or cold. This helps engineers pick the right valve for the system’s pressure.

Can the API594 dual plate check valve work with corrosive fluids?

A216 WCB carbon steel is used for most fluids. For fluids that cause rust or damage, engineers use stainless steel or special alloys. Always make sure the valve material matches the fluid before you choose.

Tip: Ask the manufacturer for help picking the right material for strong chemicals.

How does the wafer-type connection help with installation?

The wafer-type connection goes between two pipe flanges. This saves space and makes installation faster. The valve is small, so it is easy to move and put in tight spots.

评论

发表评论