Key Features and Benefits of 3 Inch Gate Valve ASTM A105N 1500 LB

The 3 inch gate valve is special in factories because it is made from forged steel and has a strong build. This valve follows global rules, so it is reliable and strong in places with high pressure. Companies in oil and gas, power plants, and chemical factories use this valve because it works in many ways and always does its job well.

Key Takeaways

The 3 Inch Gate Valve ASTM A105N 1500 LB is made from strong forged steel. This makes it tough and long-lasting for high-pressure jobs in factories.

This valve has different connection types like butt-weld, socket-weld, threaded, and flanged. These options help make it easy to put in and take care of in many pipe systems.

Its sealing system has a pressure seal bonnet and metal-to-metal seats. This stops leaks even when things get hard, so it stays safe to use.

The valve works in many places like oil and gas, power plants, chemical plants, and water treatment. It can handle many temperatures and pressures.

Picking the right valve means checking pressure ratings, materials, and connection types. Good installation and regular checks help it work well and last longer.

3 Inch Gate Valve Specifications

Size and Dimensions

The 3 inch gate valve fits pipes that are 3 inches wide. This size lets it work in many factories. The valve is small, so it fits in tight spots. Its reducer port design helps control how things flow. This makes sure it works well in high-pressure places.

Material

ASTM A105N forged steel is used for the body and disc. This steel is strong and tough. It helps the valve work well under stress. The stem and bonnet can be made from F6a, F11, F22, F304, or F316. The choice depends on what the valve will do. Forging and normalizing make the valve last longer and safer.

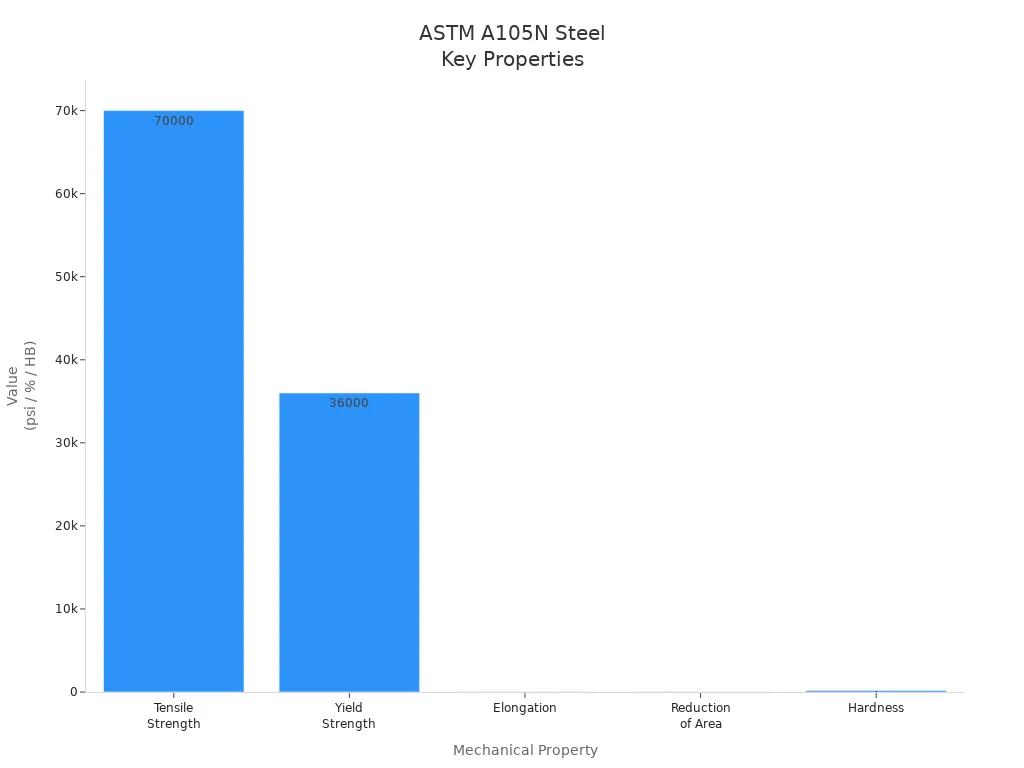

The table below lists the main mechanical properties of ASTM A105N forged steel and how they help the valve work:

Mechanical Property | ASTM A105N Value | Impact on Valve Performance |

|---|---|---|

Tensile Strength (min) | 70,000 psi (485 MPa) | Withstands high pressure |

Yield Strength (min) | 36,000 psi (250 MPa) | Resists deformation |

Elongation | 22% | Absorbs stress |

Reduction of Area | 30% | Toughness |

Hardness (max) | 187 HB | Wear resistance |

Pressure Rating

This valve has a pressure rating of 1500 LB. It works safely in high-pressure systems. The temperature range is from -29°C to 425°C. These features make it good for tough places like oil and gas plants.

Standards

The 3 inch gate valve follows important industry rules:

BS 5352: Checks quality and how well forged steel valves work.

API 602: Lists design and making steps.

API 598: Sets rules for checking leaks and pressure.

ANSI B16.25: Explains butt-welded end connections.

End Connections

This valve has different end connection types. Each type has its own good points:

End Connection Type | Description | Advantages |

|---|---|---|

Socket-Weld (SW) | Pipe goes into a small space and is welded. | Makes strong, leak-proof joints for high pressure. |

Threaded | Has threads to screw onto pipes. | Easy to put on and take off. |

Flanged | Flanges bolt to matching pipe flanges. | Simple to fix and line up. |

Butt-Weld (BW) | Welded right to the pipe ends. | Makes a secure, lasting connection. |

These choices help the valve fit many pipe systems. They also make it easy to take care of.

Features

Construction

The 3 Inch Gate Valve ASTM A105N 1500 LB has a strong steel body. This makes the valve tough and long-lasting. The reducer port design helps control how things move through it. This is good for places with high pressure. Engineers can pick from different stem and bonnet materials like F6a, F11, F22, F304, or F316. This lets the valve work for many jobs. There are many ways to connect the valve, such as butt-weld, socket-weld, threaded, and flanged. These choices make it easy to put in and use.

Sealing

Sealing is a very important part of this valve. The pressure seal bonnet gets tighter when the inside pressure goes up. This keeps leaks from happening, even when things get tough. The valve uses metal-to-metal seats for a tight close. Hard coatings like Stellite or Tungsten Carbide make the seats last longer and seal better. The bolted bonnet keeps the inside parts safe and helps stop leaks. Graphite stem packing seals around the stem. The anti-blowout stem design adds more safety.

These sealing features work together to stop leaks in high-pressure places.

Corrosion Resistance

ASTM A105N forged carbon steel helps stop rust. This material works well in rough places like oil, gas, and chemical plants. The welded flange and rising stem design help the valve work well and make fixing it easier. The valve does not resist rust as much as stainless steel. But it still protects well in most factories.

Operation

People use a handwheel to open or close the valve. This simple part lets you adjust the valve easily. The reducer port design helps keep the flow smooth and steady. The valve is made so it is easy to use, even when pressure is high. You can connect the valve in many ways to fit different pipes.

The handwheel lets users control the valve.

The reducer port design helps flow move well.

Many connection types make it easy to put in or take out.

Inspection

Makers check each valve using strict rules. They test and inspect the valves by API 598 to look for leaks and check pressure. The table below shows some rules used to test and check valves:

Valve Specification | Testing and Inspection Standard |

|---|---|

ASTM A105N, 1 Inch, 1500 LB Gate Valve | API 598 |

ASTM A105N, 1 Inch, 1500 LB Gate Valve | API 598, API 6D, EN 12266-1, EN 1074-1, ISO 5208 |

ASTM A105N, 3/4 Inch, 1500 LB Forged Gate Valve | API 598 |

These checks make sure every valve is safe and works well before it is sent out.

Benefits

Reliability

Engineers like this valve because it works well every time. The forged steel body is strong and can handle hard hits. Each valve is checked and tested before it leaves the factory. This careful checking makes sure the valve always does its job. Operators can trust it to control flow without breaking.

Longevity

The 3 Inch Gate Valve ASTM A105N 1500 LB lasts a long time. Its forged steel body is strong and tough. Hard coatings on the seats help stop wear. The stem and bonnet are made from special alloys. These alloys keep them safe from heat and chemicals. All these things help the valve work for years, even in rough places.

Note: Using the valve often does not wear out the main parts fast. This means factories do not need to replace it often or stop work much.

Maintenance

Maintenance teams think this valve is easy to fix. The design lets workers get to the inside parts fast. The handwheel makes opening and closing simple. There are many ways to connect the valve, like butt-weld and flanged ends. This helps workers take it out or put it in without problems. The anti-blowout stem and good sealing system help stop leaks. This means workers do not have to check it as much.

Taking the valve apart is quick and easy.

Fewer leaks mean less fixing in a hurry.

Clear rules for checking help teams find problems early.

Versatility

This valve works in many kinds of factories. Oil and gas plants, power stations, and chemical factories use it. It can handle hot or cold places because of its wide range. Engineers can pick different stem and bonnet materials for their needs. The valve fits many pipe systems, so it is good for new jobs or upgrades.

Industry | Application Example |

|---|---|

Oil & Gas | Pipeline isolation |

Power Generation | Steam line control |

Chemical Plants | Process flow management |

Water Treatment | Main line shut-off |

3 Inch Gate Valve Applications

Oil and Gas

Oil and gas sites use the 3 inch gate valve for safe flow control. Workers use this valve to shut off parts of pipelines during repairs or emergencies. The forged steel body can handle high pressure and big temperature changes. The reducer port design helps control flow and stops rough movement inside the pipe. This makes the valve a good pick for both starting and ending parts of oil and gas work.

Power Generation

Power plants need strong valves for steam, water, and fuel lines. The 3 inch gate valve works well because it stands up to heat and pressure. Plant workers use it to stop or start flow in main pipes. The handwheel lets them make quick changes. The tough build means the valve lasts a long time, even in hard places.

Chemical Plants

Chemical plants need equipment that can handle strong chemicals and high pressure. The 3 inch gate valve is good for this because it has a forged carbon steel body and seals tightly. Workers can pick different packing materials to help stop rust. The table below shows how this valve helps in chemical plants:

Feature | Description | Benefit in Chemical Plant Operations |

|---|---|---|

Material | Forged carbon steel (ASTM A105N) | Strong build for high pressure and heat |

Pressure Rating | Class 150 LB to 1500 LB | Works well in tough factory jobs |

Body-Bonnet Connection | Bolted bonnet with gasket and RTJ ring sealing | Keeps leaks away and lasts long |

Packing | Graphite or PTFE packing, API 622 fugitive emission packing | Stops rust and meets safety rules |

Seat | Renewable seats and back seats available | Seals well and is easy to fix |

Actuation | Handwheel, gearbox, electric, pneumatic options | Many ways to open and close for different needs |

Standards Compliance | API 600, ASME B16.34, ISO 15848 (fugitive emission design) | Meets important safety and quality rules |

Operation | Designed for isolating and controlling process fluids under high pressure and corrosive conditions | Keeps chemical plants safe and running well |

Water Treatment

Water treatment plants use the 3 inch gate valve to control water, air, and other fluids. The forged carbon steel body does not wear out fast or rust easily. This makes it great for these jobs. Workers pick this valve because it can open or close all the way, giving a tight seal and letting water move easily. The valve can handle high pressure and big temperature changes. Important things to look at are material strength, pressure rating, and how it connects to pipes. The table below shows key features:

Feature | Description |

|---|---|

Application | Used in water, air, oil, gas, including water treatment processes |

Material | ASTM A105N forged carbon steel body, disc, stem, bonnet |

Size | 3 inch |

Pressure Rating | 1500 LB |

Connection Type | Butt-welded ends (BW), flanged, socket weld, screw types available |

Design Features | Solid wedge gate design, manual or automated operation |

Standards | Conforms to ANSI, API 602, BS 5352, API 598 testing standards |

Temperature Range | -29℃ to 425℃ |

Key Role | Opens or closes fully for a tight seal and easy flow |

Selection Criteria | Material strength, pressure rating, connection type, how it works, and if it meets standards |

Other Industries

Many other industries use the 3 inch gate valve. Food factories, mining sites, and HVAC systems use it because it is strong and can do many jobs. The valve can handle many kinds of fluids and different pressures. Workers like that it is easy to put in and does not need much fixing.

Tip: Picking the right 3 inch gate valve helps keep work safe and running smoothly in any industry.

Selection Tips

Choosing the Right Valve

Picking the right 3 Inch Gate Valve ASTM A105N 1500 LB takes careful planning. Engineers need to look at what the system needs. They should check the valve’s pressure and temperature ratings. These ratings must match what the pipeline needs. The material is very important. ASTM A105N forged steel works for most fluids in factories. For special chemicals or very hot or cold places, engineers might pick other stem and bonnet alloys. Looking at the end connection type helps make sure the valve fits the pipes. A simple guide lets teams compare choices and pick the best one for each job.

Installation

Putting in the valve the right way makes sure it works well. Workers should look at the valve for any damage before starting. They need to clean the pipe ends and take out any dirt. Lining up the valve with the pipe stops stress on the body and ends. Using the right welding or bolts keeps the valve in place. After putting it in, workers should open and close the valve a few times. This checks that it works smoothly and seals tight. Checking the valve during startup helps find problems early.

Performance Optimization

Getting the best from the 3 Inch Gate Valve ASTM A105N 1500 LB means following some key steps:

Check each valve closely. Look for marks or cracks and test for leaks at both low and high pressure.

Pick the right materials and use good heat treatment. This makes the valve harder and stronger for tough jobs.

Make sure all sizes and wall thicknesses are correct. Good sizing helps the valve handle high pressure and stops rust.

Change how the valve is made to fit the job. Pick surface finishes that last long and follow rules.

Train inspection workers often. Skilled workers can find problems early and stop failures.

Use valves with trusted certifications like ISO, ASTM, or ASME. Certified valves meet important quality rules.

Do regular sample tests. Ongoing checks help keep the valve safe and working for a long time.

Tip: Doing these things helps the valve work well and last longer in hard factory jobs.

The 3 Inch Gate Valve ASTM A105N 1500 LB is strong because it is made from forged steel. It seals tightly so leaks do not happen. You can connect it to pipes in different ways. This valve follows tough industry rules. It works well when the pressure is high.

Engineers know it will work for a long time.

Operators think it is simple to put in and fix.

When picking gate valves, look at these features. This helps keep work safe and things running well in hard jobs.

FAQ

What industries use the 3 Inch Gate Valve ASTM A105N 1500 LB?

Oil and gas plants use this valve a lot. Power plants and chemical factories also use it. Water treatment places pick it for its strength. Many other industries like it because it is strong and works well.

How does the valve prevent leaks?

The valve has a pressure seal bonnet and metal-to-metal seats. These parts help stop leaks by making a tight seal. Graphite stem packing and an anti-blowout stem give more safety.

Can the valve handle corrosive fluids?

Yes, it can. The valve has stem and bonnet choices in alloys like F304 or F316. These materials help stop rust and work well with many chemicals.

What end connections are available?

You can pick butt-weld, socket-weld, threaded, or flanged ends. Each type works with different pipes and ways to put it in.

How often should the valve be inspected?

Checking the valve often keeps it safe to use. Most places look at valves during regular checks or after big changes to the system.

评论

发表评论