Soft Seat Ball Valve vs Metal Seat Ball Valve Which Is Right for Your System

Choosing between a soft seat ball valve vs metal seat ball valve depends on your system’s specific requirements. You need to consider factors like temperature, pressure, sealing capability, and cost. The table below highlights the key differences:

Factor | Metal Seat Ball Valve | Soft Seat Ball Valve |

|---|---|---|

Temperature | Handles up to about 550ºF | |

Pressure | Suitable for medium to high pressure | Suitable for low pressure |

Sealing | Durable metal-to-metal seal | Flexible, very tight seal |

Cost | Higher cost but longer lifespan | Lower cost and more economical |

When deciding between a soft seat ball valve vs metal seat ball valve, metal seat valves are ideal for demanding applications or extremely high temperatures. On the other hand, soft seat ball valves provide better shutoff and cost savings in clean, low-pressure environments.

Key Takeaways

Soft seat ball valves close tightly and are cheaper. They work well in clean systems with low pressure and chemicals.

Metal seat ball valves can take high heat and pressure. They also handle rough fluids and last longer in hard jobs.

Pick soft seats if you want a tight seal and easy use. Choose metal seats if you need them to last and handle high heat.

Make sure the valve seat fits your fluid, heat, and pressure. This helps stop leaks and keeps things safe.

Ask an expert for help with hard or important systems. This helps you pick the right valve and saves money.

Soft Seat Ball Valve vs Metal Seat Ball Valve

Key Differences

When you look at a soft seat ball valve vs metal seat ball valve, you see they are built differently.

Soft seat ball valves have seats made from plastics like PTFE, RPTFE, nylon, PEEK, or Devlon. These plastics help the valve seal well and work with many chemicals.

Metal seated valves use strong metals like stainless steel, MONEL, or have coatings such as chromium carbide or tungsten carbide. These metals make the valve tough and able to handle hard jobs.

Here is a table that shows the main differences:

Aspect | Soft Seat Ball Valves | Metal Seated Ball Valves |

|---|---|---|

Seat Material | SS304, SS316, MONEL, cobalt alloys, hard coatings | |

Sealing Properties | Makes a tight seal | Seals well in tough conditions |

Suitable Fluids | Clean fluids, normal temperature and pressure | Abrasive, dirty fluids, high temperature and pressure |

Temperature Resistance | Not for very high temperatures | |

Pressure Resistance | Works at normal pressure | Handles high pressure and shock |

Durability | Wears out faster from erosion or corrosion | Stays strong against erosion and corrosion |

Operating Torque | Needs less force to turn | Needs more force to turn |

Installation | Easier to install because seats are flexible | Harder to install |

Cost | Costs less at first | Costs more but lasts longer |

Application Preference | Good for tough jobs and dirty fluids |

Soft seat ball valves are best for clean systems with low pressure. Metal seated valves are made for rough places with high pressure or heat.

Sealing and Performance

Sealing is very important when picking a soft seat ball valve vs metal seat ball valve. Soft seat valves seal very well. They can stop leaks so no bubbles get through during tests. This is great for places where leaks are not allowed, like chemical or medicine factories.

Metal seat valves do not always seal perfectly. They let a tiny bit of fluid leak, usually less than 0.01% of what the valve can hold. This is still very little and meets safety rules. Metal seat ball valves work well in tough places, like high heat, rough fluids, or when used a lot. They last a long time and do not wear out fast, even if they do not seal as tightly.

Feature | Soft Seat Ball Valve | Metal Seat Ball Valve |

|---|---|---|

Seals very well, no bubbles leak | Seals well, but some small leaks allowed | |

Wear Resistance | Wears out faster if scratched | Lasts longer, good for lots of use |

Suitability for High-Cycle Applications | Wears out faster over time | Works well for many uses, stays strong |

Operating Torque | Needs less force to turn | Needs more force to turn |

Tip: If you need no leaks, pick a soft seat ball valve. If you want a valve that lasts in tough places, choose a metal seat valve.

Temperature and Pressure Limits

Temperature and pressure are important when choosing a valve. Soft seat ball valves can handle heat up to about 572°F if you use special PTFE seats. Most soft seats start to break down above 450°F. They work best at normal pressure.

Metal seat valves can handle much higher heat and pressure. Many meet safety standards and can work at very high pressure and heat, up to 1200°F or more. This makes them good for hard jobs, like steam, melted metals, or high-pressure gas.

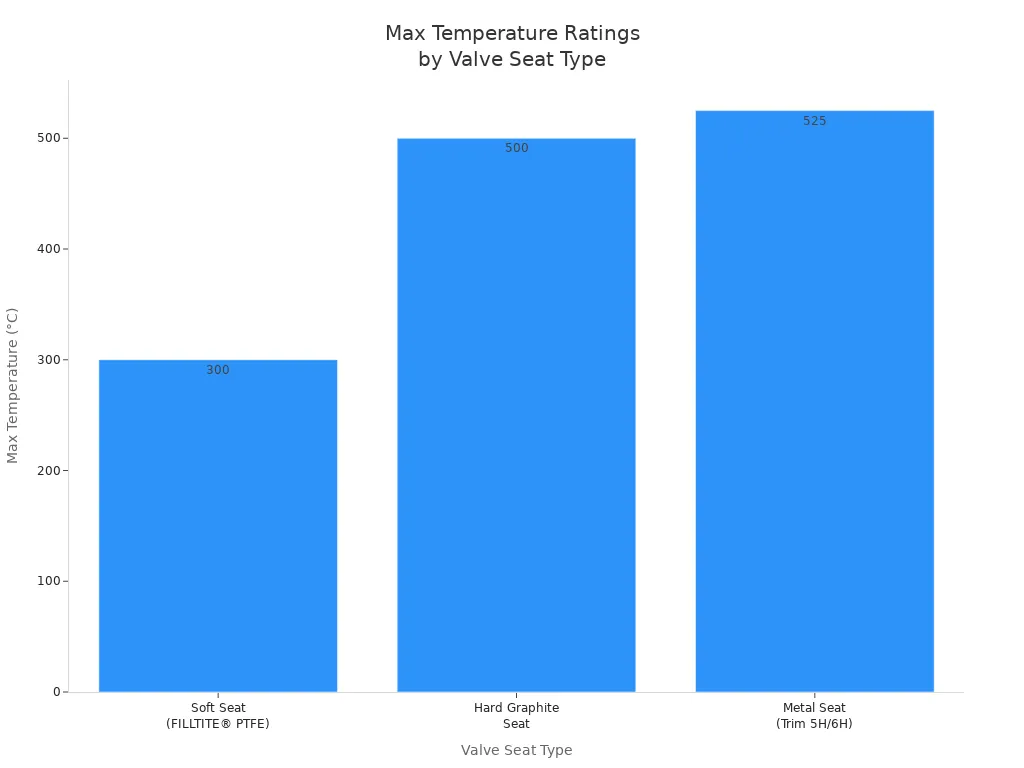

Here is a chart that compares how much heat different seats can take:

Note: If your system gets hotter than 450°F or has very high pressure, you should use metal seat valves.

Typical Applications

Soft seat ball valves and metal seat ball valves are used in different places. Soft seat valves are found in chemical plants, medicine factories, and places that need good sealing and work with chemicals. They are also used in clean water systems and some water treatment plants where the fluid is not rough.

Metal seat valves are used in oil and gas, power plants, mining, and water treatment plants that handle rough or dirty fluids. These valves can take high heat, high pressure, and fluids that can scratch or wear out other valves. You see them in places like steam pipes, reactors, and high-pressure gas pipes.

Industry / Sector | Preferred Ball Valve Seat Type | Reason / Characteristics |

|---|---|---|

Soft Seat | Needs tight sealing and works with strong chemicals. | |

Pharmaceutical | Soft Seat | Needs to work with chemicals and seal tightly. |

Oil and Gas | Metal Seat | |

Power Generation | Metal Seat | Needs to be strong and reliable in high pressure. |

Petrochemical | Soft Seat | Uses soft seats for chemical resistance and sealing. |

Water and Wastewater Treatment | Metal Seat | Needs to last and be strong in tough places. |

In short, pick a soft seat ball valve vs metal seat ball valve based on what your system needs. For clean, low-pressure, and chemical fluids, soft seat valves seal well and save money. For rough, hot, or dirty places, metal seat valves last longer and work better.

Soft Seated Ball Valves

Advantages

Soft seated valves have many good points for your system.

They seal very well because the soft seat fits tightly on the ball. This helps stop leaks and keeps the valve closed tight.

You do not need much force to turn these valves. You can use your hand or a machine to open or close them.

Because they need less force, the parts do not wear out as fast. This helps the valve last longer and means you do not have to fix it often.

Soft seated valves cost less than metal seated ones. This makes them a good choice if you want to save money.

In systems that use machines to open and close valves, the lower force also uses less power. This saves you money over time.

The soft seat can handle small bits of dirt better. This means you will have fewer problems if there is a little debris.

Tip: Soft seated ball valves help you spend less time fixing things in automated systems. Their design makes them easy to put in, quick to repair, and you can even control them from far away with machines.

Disadvantages

There are also some things soft seated valves cannot do.

The soft seat, like PTFE or elastomers, can get damaged by strong chemicals, high heat, or rough fluids.

If the pressure is high or the fluid moves fast, the seat can wear out and start to leak.

Very hot or strong chemicals can make the seat hard or change its shape. This can make the valve not seal well.

If you pick the wrong seat for your fluid, the valve will not last long.

Too much heat or pressure can break the seat and make the valve stop working.

You should check your valve often and pick the right seat for your fluid. This helps your soft seated ball valve work well for a long time.

Best Uses

Soft seated valves work best in clean systems with low pressure.

They are great for the pharmaceutical and food processing industries. These places need valves that shut tight and keep delicate things safe.

You can also use them in chemical plants, water treatment, and other places where you need a good seal but do not have high heat or rough fluids.

If you need a valve that opens and closes a lot or works with machines, soft seated ball valves are a smart pick. They are easy to use and take care of.

Note: Always make sure the seat matches your fluid and temperature. This helps your soft seated valves work their best and last longer.

Metal Seated Ball Valves

Advantages

Metal seated ball valves are great for tough jobs. They can handle heat over 1000°F and work under high pressure. You will see them in power plants, chemical factories, and oil and gas fields. The metal to metal seat makes them strong and hard to wear out. Here are some main advantages:

Metal seated valves do not rust or wear down easily. They use strong metals like stainless steel or tungsten carbide.

They keep a good seal, even with lots of heat or pressure.

The seats clean themselves, so dirt does not block the valve. This is good for rough jobs.

These valves last longer and need less fixing than soft-seated valves.

Some are fire-safe, so they protect your system if there is a fire.

They work well with rough fluids, strong chemicals, and fast flows.

Note: Metal seated ball valves are best for mining, pulp and paper, and power plants. They are very tough and do not wear out fast in hard places.

Disadvantages

Metal seated valves have some problems too. They usually cost more at first than soft-seated valves. They may not seal as tight, so small leaks can happen. Here are some common problems:

Metal seated ball valves may leak more than soft-seated valves.

They cost more to buy, especially if you need special types.

You have to check and fix them more in places with strong chemicals. This keeps the metal in good shape.

Fixing them can be harder because they are built strong.

Tip: If you need the best seal for clean, low-pressure jobs, pick a soft-seated valve.

Best Uses

Use metal seated ball valves when your system is very tough. They are best for rough jobs, high heat, and high pressure. Here are some good uses:

Power plants: They handle very hot steam and high pressure.

Oil and gas: They work with rough fluids and high-pressure gas.

Chemical plants: They work with strong and rough chemicals.

Mining and slurry: They are good for moving solids and slurries.

Pulp and paper: They do not wear out from strong chemicals.

Industry | Why Choose Metal Seated Valves? |

|---|---|

Power Generation | Very tough, handles high heat |

Oil & Gas | Works with rough and high-pressure fluids |

Chemical Processing | Does not rust or wear down easily |

Mining | Lasts long in rough jobs |

Pulp & Paper | Stays strong with harsh chemicals |

You should use metal seated valves if soft seats would break from heat, pressure, or rough stuff. They last longer and are a smart choice for hard jobs.

Choosing the Right Valve

Matching to System Needs

When you pick a valve, you need to think about your system. Every system is different. You should know what goes through your pipes. You also need to check how hot or cold it gets. Pressure in the system is important too. The seat you choose depends on these things.

Here are some things to look at:

Make sure the seat matches the fluid or chemicals. PTFE works with many chemicals. Metal seats are better for high heat or rough fluids.

Check the temperature range. Soft seats like PTFE can take heat up to 450°F. Metal seats can handle much higher heat.

Look at the pressure. Soft seats are good for low or medium pressure. Metal seats work best for high pressure.

Think about how clean or dirty your fluid is. Soft seats are good for clean fluids. Metal seats are better for dirty, rough, or corrosive fluids.

Pick the right valve body material. Stainless steel, brass, and plastic are all different.

Think about how often you will use the valve. If you open and close it a lot, you may need a tougher seat.

Tip: Always match the seat and body to your fluid, temperature, and pressure. This helps stop leaks and keeps your system safe.

Comparison Checklist

You can use this checklist to help pick between soft seat and metal seat ball valves:

Comparison Item | Soft Seat Ball Valves | Metal Seat Ball Valves |

|---|---|---|

Material Composition | PTFE, RPTFE, Nylon, PEEK, Delrin | Stainless steel, copper alloys, nickel alloys, hard coatings |

Suitable Media | Air, water, non-corrosive fluids | Hot water, gas, oil, acids, alkalis, corrosive fluids |

Working Pressure | Low to medium | Medium to high |

Working Temperature | Up to 260°C (550°F) | Up to 540°C (1000°F+) |

Sealing Performance | Bubble-tight, zero leakage | Good, but may allow small leaks |

Abrasion Resistance | Low | High |

Durability | Shorter in harsh conditions | Longer, especially in tough jobs |

Initial Cost | Lower | Higher |

Maintenance Needs | More frequent in tough jobs | Less frequent, more durable |

Torque Requirements | Lower, easy to operate | Higher, needs more force |

Application Suitability | Clean, low-pressure, frequent use | High temp, high pressure, dirty or corrosive fluids |

Note: Use this table to see which valve is best for your job. This helps you make a good choice and avoid problems later.

Cost and Value

Cost matters, but you should also think about value over time. Soft seat ball valves cost less at first. They work well in clean, low-pressure systems. If your job is simple, you can save money with soft seats.

Metal seat ball valves cost more to buy. They last longer in tough places. You spend less fixing them and have less downtime. Over time, metal seats can save money, especially in hard or important jobs.

Aspect | Soft-Seated Ball Valves | Metal-Seated Ball Valves |

|---|---|---|

Initial Cost | Lower | Higher |

Service Life | Shorter in harsh jobs | Longer, even in tough jobs |

Maintenance | More frequent in rough conditions | Less frequent, more reliable |

Total Cost of Ownership | Higher in harsh jobs due to repairs | Lower over time in severe service |

Best Value For | Simple, clean, low-cost systems | Critical, high-temp, high-pressure systems |

Remember: The cheapest valve is not always the best for your system. Think about how much you will spend fixing or replacing it over time.

When to Consult an Expert

Sometimes, you need help from a valve expert. You should talk to an expert if:

Your system uses special or dangerous fluids.

You have high pressure or very hot or cold temperatures.

Your job is very important or must follow strict rules.

You need help picking the right size, material, or actuator.

You want to avoid mistakes that could cause leaks or failures.

You need a custom valve or special solution.

Experts help you pick the best valve for your system. They make sure you follow safety rules and avoid costly mistakes. Getting advice early can save you time and money.

Common mistakes people make without expert help include:

Picking the wrong material for the fluid.

Not checking pressure or temperature ratings.

Forgetting about how to open or close the valve.

Not planning for repairs.

Choosing a poor-quality supplier.

Tip: If you are not sure or your system is tricky, always ask an expert before you buy.

When you pick between soft seated and metal seated valves, you have some big choices to make. The table below shows the main things to think about:

Decision Point | Soft Seated (API 607) | Metal Seated (API 608) |

|---|---|---|

Fire Safety | High, fire-tested | Optional, dual-certified |

Best For | Leak prevention, purity | High temp, pressure, durability |

Maintenance | More frequent | Less frequent |

Make sure your valve fits your system’s needs. Think about temperature, pressure, and what flows inside.

Use the table to help you decide which valve is best.

If your job is very important or tough, talk to a valve expert for help.

FAQ

What is the main difference between soft seat and metal seat ball valves?

Soft seat ball valves use plastic or elastomer seats for a tight seal. Metal seat ball valves use metal seats for strength and durability. You should choose based on your system’s temperature, pressure, and fluid type.

Can I use a soft seat ball valve for high-temperature applications?

You should not use a soft seat ball valve for high temperatures. Most soft seats start to break down above 450°F. For high heat, you need a metal seat ball valve.

How do I know which seat material is best for my fluid?

Check the chemical compatibility of your fluid with the seat material. PTFE works with many chemicals. For strong acids, bases, or abrasive fluids, you may need a special seat or a metal seat.

Do metal seat ball valves always leak more than soft seat valves?

Metal seat ball valves may allow tiny leaks, but they still meet safety standards. Soft seat valves usually provide a bubble-tight seal. If you need zero leaks, choose a soft seat valve.

Are metal seat ball valves harder to maintain?

Metal seat ball valves last longer in tough jobs, but repairs can be more complex. You may need special tools or skills. For simple maintenance, soft seat ball valves are easier to handle.

评论

发表评论