What Are the Key Features of Triple Eccentric Butterfly Valves

Triple eccentric butterfly valves are special because of their smart design and strong performance. Some important features are:

Triple eccentric offset mechanism helps lower friction and wear

Metal-to-metal sealing gives a tight shutoff with no leaks

Works well in places with high pressure and high heat

Needs less force to operate and lasts longer because of strong materials

Small, affordable butterfly valve design that is easy to automate

This valve can handle tough liquids and follows strict safety rules. Many industries like oil and gas use triple eccentric butterfly valves for hard jobs. The 48-inch flange butterfly valve shows these features in real use.

Key Takeaways

Triple eccentric butterfly valves have three offsets. This helps cut down friction and wear. They last longer and work better.

They use a strong metal-to-metal seal. This seal stops leaks, even with high pressure and heat.

These valves can handle harsh chemicals and tough conditions. They are reliable for many jobs like oil, gas, and water treatment.

Their smart design saves energy and money. They need less force to use and do not break often.

Many industries trust these valves for safe shutoff. They also give good flow control in hard places.

Triple Eccentric Design

Offset Mechanism

The triple eccentric butterfly valve is special because of its offset mechanism. It uses three different offsets to change how the valve works and seals. Each offset helps the valve work better.

Offset Number | Description | Engineering Role |

|---|---|---|

First Offset | Shaft is behind the sealing surface | Makes a smooth seat path and stops rubbing |

Second Offset | Shaft is to one side of the centerline | Lets the seal move away from the seat, lowering friction |

Third Offset | Seat and seal cone centerlines are tilted | Stops rubbing between disc and seat, allowing metal-to-metal sealing |

The first offset puts the shaft behind the sealing surface. This lets the sealing line go all the way around the seat and helps stop friction. The second offset moves the shaft away from the middle of the valve. This lets the disc move away from the seat fast when the valve opens. The third offset tilts the sealing surface to make a cone shape. This cone shape makes a twist seal, not just a simple seal. The disc and seat only touch at the end of closing, so there is less wear.

Note: The triple eccentric design changes the sealing surface from a circle to an oval. This new shape lets the valve seal by twisting, not by pressing straight down. This makes the seal tight and strong, even when pressure and temperature are high.

The triple eccentric design uses hard alloys on the sealing surfaces. These materials fight rust and heat, so the butterfly valve can handle tough jobs. The triple offset butterfly valve works better in hard conditions than older designs.

Friction Reduction

The triple eccentric butterfly valve lowers friction in many ways. The three offsets work together so the disc and seat do not rub most of the time. The disc only touches the seat at the very end of closing. This helps stop wear.

The first offset puts the valve stem behind the sealing surface, making a smooth seat.

The second offset moves the stem away from the center, so the disc can move away from the seat fast.

The third offset tilts the sealing surface, making a cam-like action that stops scraping.

This triple eccentric shape means the butterfly valve works with almost no friction. The valve needs less force to open and close, so it saves energy. The design also helps the valve last longer. Studies show triple eccentric valves last up to 40% longer than regular butterfly valves. They break less and need less fixing. Power plants and chemical factories like these valves because they save money and lower downtime.

The disc only touches the seat at the end, so there is less wear.

The triple eccentric design makes a cam action, so the valve works smoothly.

Less friction means less force needed and less fixing.

These valves seal tightly, even in tough places.

The triple eccentric butterfly valve gives a strong and long-lasting answer for places that need good shutoff and control. Its smart design makes it a top pick for high-pressure, high-temperature, and corrosive jobs.

Sealing and Shut-Off

Metal-to-Metal Seal

A triple eccentric butterfly valve uses a metal-to-metal seal. This seal stops leaks and keeps systems safe. It is different from soft-sealing valves. It uses strong metals, not rubber or plastic. The body is often made from carbon steel or stainless steel. The disc can have a Stellite hard-facing layer. These hard materials help the valve work in high heat and pressure.

Component | Common Materials Used |

|---|---|

Body | Carbon Steel (WCB, LCB, LC1), Stainless Steel (CF8), Alloy Steel |

Disc | Carbon Steel (WCB), Stainless Steel (CF8, CF8M), Alloy Steel |

Stem | Stainless Steel (SS420, SS304, SS316, 17-4Ph, Duplex SS) |

Sealing Materials | Stainless Steel (304, 316), Graphite, Metal-to-metal hard facings |

Corrosion resistant alloys help the valve seal well. These alloys protect against chemical damage. They keep the sealing surfaces strong. In places with seawater or weak acids, stainless steel and special alloys help the valve last longer. For very harsh chemicals, engineers use super alloys like Hastelloy or titanium. These choices make sure the hard seal butterfly valve works in tough jobs.

Note: The metal-to-metal seal in a hard seal butterfly valve does not wear out fast. It can handle many open and close cycles without losing its tight seal.

The triple eccentric design helps the valve seal better. The disc and seat only touch at the end of closing. This lowers friction and stops damage. The hard seal butterfly valve can handle high pressure and heat without leaking.

Zero Leakage

Zero leakage means no fluid gets through when closed. The triple eccentric butterfly valve meets strict API 609 standards for zero leakage. These rules check the valve’s design, size, and seal. The valve uses a special cam action and a strong metal seat to stop leaks. The seat often has a hard surface, like STL one-piece. This makes it last longer and easier to fix.

The triple eccentric butterfly valve uses three offsets. These offsets stop the disc from touching the seat most of the time. This cam effect keeps the seat from wearing out and helps prevent leaks.

The valve uses a composite metal sealing ring and torque seal. This gives two-way zero leakage, so it works in both flow directions.

The hard seal butterfly valve has an all-metal, fireproof build. This makes it safe and leak-tight, even in emergencies.

Anti-blowout stems add extra safety and help the valve meet API 609 rules.

Zero leakage helps many important industries:

The valve keeps a 0% leakage rate, even at high pressures like 200 psi. This keeps the system safe and reliable.

Energy use drops by up to 80% compared to other valves. This saves money and helps the environment.

The valve needs less fixing and checking. It can adjust itself over time, so workers spend less time on repairs.

System performance gets better. The valve gives accurate data for building management systems, making control easier.

Fast programming and easy troubleshooting help keep the system running with less downtime.

A hard seal butterfly valve with zero leakage protects people, equipment, and the environment. It gives peace of mind in places where even a small leak could cause big problems.

Performance in Extreme Conditions

High Temperature

Triple eccentric butterfly valves work well when it gets very hot. Their metal-to-metal seal and special shape help stop leaks, even if the heat goes up. The valve body and disc are made from strong metals like stainless steel or carbon steel. These metals can take a lot of heat and still stay strong.

Valve Type / Material | Maximum Temperature Rating |

|---|---|

Standard triple eccentric butterfly valve | +400 °C |

Extended rating (depending on body material) | Up to +550 °C |

Metal seated triple eccentric valve | |

Stainless steel CF3 triple eccentric valve | Up to 425 °C |

The triple offset design keeps the sealing parts from rubbing together. This means less damage and helps the valve last longer, even when it gets hot. The hard seal and wedge seat help the valve stay tight, even if the temperature changes a lot.

Note: Triple eccentric butterfly valves get special hardening on their sealing parts. This makes them tough against heat and wearing out.

High Pressure

Triple eccentric butterfly valves are made for high pressure jobs. The three-offset design lets the disc press tightly on the seat. This design cuts down on rubbing and helps the valve work well in hard jobs.

Pressure Class (ASME/ANSI) | Typical Ratings |

|---|---|

Class 150 | CL150 |

Class 300 | CL300 |

Class 600 | CL600 |

Class 900 | CL900 |

Class 1500 | CL1500 |

These valves can handle pressure from CL150 up to CL1500. The triple offset design seals better than a two-offset butterfly valve. This makes it a good pick for oil, gas, and power plants.

The valve keeps leaks out, even with high pressure.

The design helps the valve last longer and wear less.

Corrosive Media

Triple eccentric butterfly valves can stand up to many harsh chemicals. The metal seat and body use special metals to stop rust and chemical harm. Some common metals are stainless steel, duplex steel, and nickel alloys like Inconel and Hastelloy.

Stainless steels (304, 316, 316L) work with water, acids, and seawater.

Duplex steels (2205, 2507) fight off strong acids.

Nickel alloys can handle tough chemicals and salts.

Some valves have PTFE or PFA linings for more safety.

Extra coatings like Stellite or ceramic make the valve even tougher. These things help the butterfly valve work in chemical plants, ships, and water cleaning places.

Triple eccentric butterfly valves can control flow or stop it fully. Their strong seal and tough build make them great for hot, high-pressure, or chemical jobs.

Triple Eccentric vs Other Butterfly Valves

Single and Double Eccentric

Butterfly valves have three main types. These are single, double, and triple eccentric. Each type has a different way to control flow and sealing.

Valve Type | Design Features | Sealing Mechanism and Contact | Key Effects |

|---|---|---|---|

Single Eccentric | Disc offset from valve seat center to reduce extrusion between disc and seat | Slope sealing with soft seal; continuous contact causes wear | Reduces extrusion but scraping still occurs; limited application range |

Double Eccentric | Two offsets: shaft center deviates from disc and body center | Line seal (metal or soft); disc moves away from seat quickly, reducing wear | Quick separation reduces wear; good sealing; suitable for moderate pressure and temperature |

Triple Eccentric | Three offsets including a conical seat angle creating a metal-to-metal seal | Face seal (metal-to-metal); disc contacts seat only at final closure | Minimizes wear; hard metal seal; suitable for high temperature and pressure |

Single eccentric butterfly valves use one offset. This helps lower squeezing between the disc and seat. But the disc still scrapes the seat and wears out. Double eccentric valves add another offset. The disc moves away from the seat faster. This lowers wear and helps the seal work better. Triple eccentric butterfly valves use three offsets. The third offset makes a cone-shaped seat. This lets the valve use a metal-to-metal seal. The disc only touches the seat at the end, so there is almost no wear.

Key Differences

The biggest differences are in sealing, how long they last, and where they work best.

Single eccentric valves have soft seals. They are good for water and low pressure but wear out quickly.

Double eccentric valves last longer. They use soft or metal seals and work with medium pressure and heat.

Triple eccentric butterfly valves use a metal-to-metal seal. This design stops leaks, even in very hot or high-pressure places.

Triple eccentric butterfly valves last longer. The disc and seat do not rub most of the time. The metal seat does not get damaged by heat, pressure, or strong chemicals. Many industries pick this valve for important jobs. These include oil and gas, power plants, and chemical plants. The triple offset design means less fixing and fewer leaks.

Note: Triple eccentric butterfly valves work in tough places. They handle superheated steam, strong chemicals, and high-pressure pipes. Their strong seal and tough build make them the best choice for safety.

Butterfly Valve Applications

Industrial Use

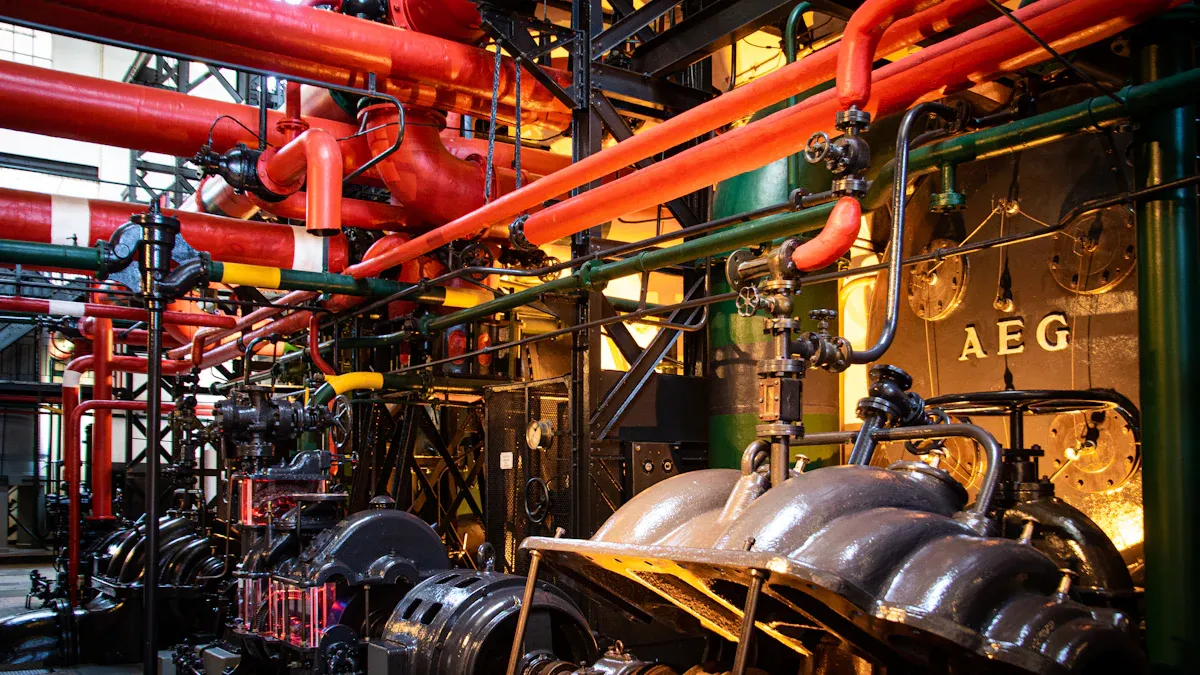

Many industries use the butterfly valve to control flow safely. Petrochemical plants use these valves to stop or control gases and liquids. In hydrocarbon processing, the butterfly valve shuts tightly and handles high pressure and heat. Water treatment plants use the valve to control flow and help with cleaning water. The food industry uses the butterfly valve to control flow and pressure when making drinks. Environmental plants use the valve to control pollution and handle waste.

People pick the butterfly valve because it has less friction, seals well, and works in tough places. The valve lasts a long time and works well, even if it costs more than some other valves. Many jobs need valves that can do hard work. The butterfly valve is good for these jobs because it has two safety parts and no dead spots. The oval cone plate and hard alloy surface help it last longer. The floating U-shaped seat keeps the seal tight and does not scratch the disc.

Hydrocarbon and petrochemical plants need valves that fight rust and damage. The butterfly valve is made of all metal, so it lasts longer and is safe. It also follows strict safety rules, so people use it for important shutoff and careful flow control.

Product Example

A real example shows how the butterfly valve works in hard jobs. The 48-inch flange butterfly valve is used in big places. This valve has a triple offset design and a metal seat. It seals perfectly and has little friction. The valve can take high heat and keeps working in tough places.

Feature | Description |

|---|---|

Valve Type | Triple Offset Butterfly Valve |

Size Range | 3 – 120 inches (includes 48-inch size) |

Design Features | Precise geometry, zero leakage, metal-seated, high-temperature operation |

Practical Benefits | Perfect sealing, minimum friction, durability, reduced wear |

Application Range | Critical applications with extreme temperatures and high-purity media |

This butterfly valve works well in hydrocarbon and petrochemical plants and other places that need strong shutoff. The triple eccentric design stops leaks and helps the valve last a long time. People trust this valve for safety and good work in the hardest jobs.

Triple eccentric butterfly valves are special because of their triple offset design. They use metal-to-metal sealing and work well in tough places. These valves do not leak and last a long time. They are easy to take care of. Engineers and workers like these features. Industry tests show these valves meet strict rules like API 609 and ASME B16.34. This means they are good for important jobs.

They seal well and stop leaks.

They are strong and save money over time.

They work well when pressure and heat are high.

The 48-inch flange butterfly valve shows how this technology gives safe shut-off and flow control in real factories. More people want these valves because they work well in hard jobs.

FAQ

What makes a triple eccentric butterfly valve different from other types?

Triple eccentric butterfly valves have three offsets. These offsets help the valve seal very well. The design lowers friction and stops wear. The valve works in places with high pressure and heat.

Can a triple eccentric butterfly valve handle corrosive chemicals?

Engineers pick metals like stainless steel or nickel alloys for these valves. The valve does not rust or get damaged by chemicals. It works safely with acids, seawater, and other strong fluids.

How does the valve achieve zero leakage?

The valve uses a metal-to-metal seal. The disc only touches the seat when closing. This design follows strict API 609 rules for zero leakage. The valve keeps systems safe.

Where do industries use triple eccentric butterfly valves?

Industries use these valves in oil and gas, chemical plants, water cleaning, and power stations. The valve controls flow and shuts off fluids in hard places.

Tip: Always check the valve’s material and rating before picking it for a job.

评论

发表评论