Why Choose a Carbon Steel Ball Valve for Your Project

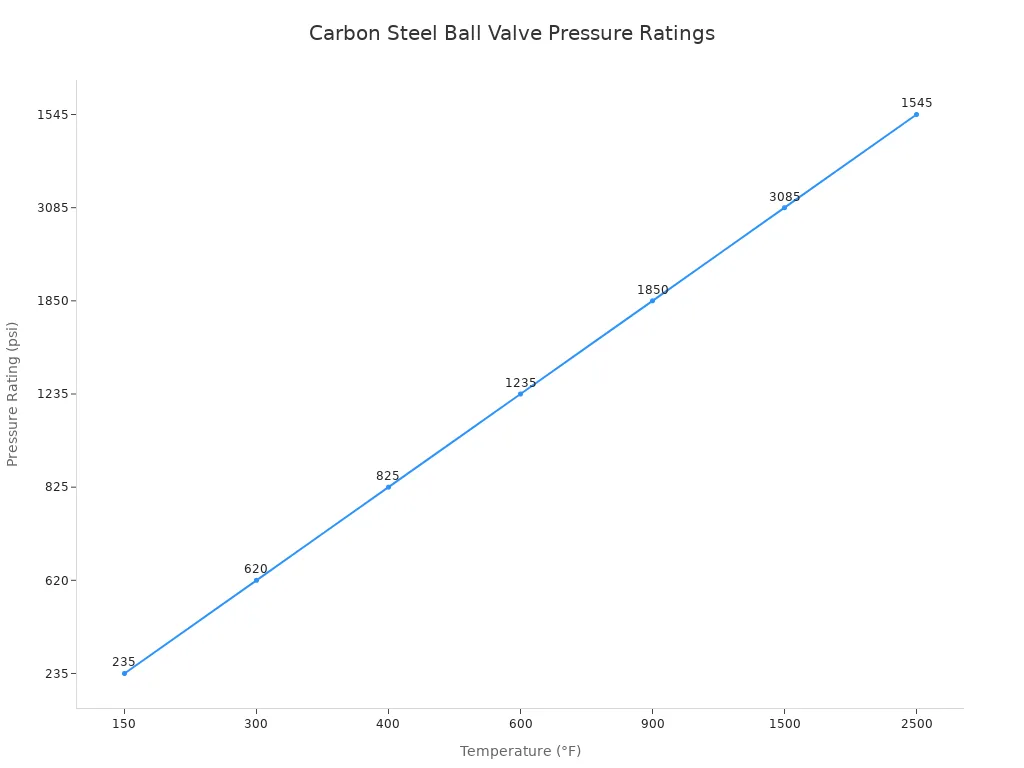

If you want a valve that is strong, pick a carbon steel ball valve. It works well when there is a lot of pressure. It also works well when it gets very hot. The table below shows how carbon steel does better than other materials. It shows the pressure ratings at different temperatures:

Temperature (°F) | Carbon Steel (PSI) |

|---|---|

150 | 235 |

300 | 620 |

400 | 825 |

600 | 1235 |

900 | 1850 |

1500 | 3085 |

2500 | 1545 |

You see carbon steel valves used in oil and gas. They are also used in many other industries. These valves work well again and again. Some have special features like full port design. Some have safety locks. The 2 Piece 2000 WOG Carbon Steel Ball Valve has these features. If you pick high pressure ball valves made from carbon steel, you get good value. You also get something you can trust for a long time.

Key Takeaways

Carbon steel ball valves are very strong and dependable. They work well in places with high pressure and heat.

These valves have a full port design. This lets more liquid flow through. It also lowers pressure drop. This helps the system work better.

Doing regular maintenance is important. You should check them every month. You should change the seals every year. This helps the valves last longer.

Safety features like blow-out proof stems help keep people safe. Handle locks also stop accidents from happening in factories.

Carbon steel valves can be used in many ways. They work with water, steam, and chemicals. This makes them good for lots of industries.

Carbon Steel Ball Valve Specs

Material Strength

When you pick a carbon steel valve, you get strong material. Carbon steel is stronger than stainless steel and brass. This means it can take more force before breaking. Here is how they compare:

Carbon steel valves are stronger than stainless steel ones.

Stainless steel (Grade 304) has a tensile strength of 621 MPa.

Brass has a tensile strength between 338 and 469 MPa.

Carbon steel’s mix of elements helps it work well. WCB material has carbon, silicon, and manganese. These make the valve tough and easy to use. You can count on it in hard jobs.

Maximum Content | |

|---|---|

Carbon (C) | Below 0.30% |

Silicon (Si) | Below 0.60% |

Manganese (Mn) | Below 1.20% |

Phosphorus (P) | Below 0.040% |

Sulfur (S) | Below 0.050% |

Carbon steel valves keep their strength in hot or cold places. This makes them a good pick for many projects.

Pressure & Temperature Ratings

You need a valve that can handle high pressure and heat. The 2 Piece 2000 WOG Carbon Steel Ball Valve does this job. It works at 2000 PSI (138 Bar) and from -10°C to 150°C. The reinforced TFE seat makes it last longer.

Feature | Specification |

|---|---|

Working Pressure | 2000 PSI (138 Bar) |

Temperature Range | -10°C thru 150°C |

Suitable Medium | WOG |

Carbon steel valves work with water, steam, air, hydrogen, ammonia, nitrogen, and oil. They can be used in systems up to 32.0 MPa and from -30°C to 425°C.

You can trust your valve if it meets world standards. The 2 Piece 2000 WOG Carbon Steel Ball Valve meets ANSI B16.34, EN 12516-1, and API 598. These rules make sure your valve is safe and works well. You can pick sizes from 1/2" to 4" for your needs.

Tip: Always check the specs before you pick a valve. This helps you avoid mistakes and keeps your system safe.

Corrosion Resistance

Corrosion resistance matters when using valves in chemical gear. If you pick the wrong material, your equipment might break. About 60% of chemical gear breaks because of corrosion. You need to choose wisely.

Carbon steel ball valves are best for low-pressure and non-corrosive jobs like oil, gas, and water.

You can add coatings like epoxy or PTFE to help stop corrosion in chemical uses.

Carbon steel is used for sodium hydroxide below 80°C and up to 30% strength. Sometimes, it can handle more heat and stronger solutions.

You can trust carbon steel valves for many jobs, but always think about what you are using them for. Coatings help your valve last longer in tough places.

Full Port Ball Valve Design

Flow Capacity

When you choose a full port ball valve, you get the best flow possible. The opening inside this valve matches the size of your pipe. This means liquid or gas can move through without getting slowed down. You do not lose flow because there are no tight spots inside the valve.

The full port ball valve has a bore that matches the pipe diameter. This allows for unrestricted flow and higher flow rates.

Reduced port valves have a smaller opening. This creates a bottleneck and limits how much fluid can pass through.

You keep your system running smoothly with a full port ball valve. It works well even when you need to move thick or sticky fluids.

Here is a quick look at why this design helps your system:

Feature | Description |

|---|---|

High Flow Capacity | The large internal diameter lets the most fluid pass through with little resistance. |

Minimal Pressure Drop | The design cuts down on turbulence and friction, so you lose less pressure as fluid moves. |

Handling Viscous Fluids | Thick or particle-filled fluids move easily, so you avoid clogs and jams. |

The 2 Piece 2000 WOG Carbon Steel Ball Valve uses this full port design. You get maximum efficiency and reliable flow in your project.

Minimal Pressure Drop

You want your system to keep its pressure. The full port ball valve helps you do that. The wide opening means fluid does not have to squeeze through a small space. This reduces resistance and keeps pressure steady.

The full port design gives you an unobstructed flow path. This means less resistance and a lower pressure drop.

Less turbulence happens inside the valve. Your system stays efficient, and you save energy.

Industries like oil and gas need to keep pressure high. The full port ball valve is a smart choice for these jobs.

Tip: If you want to boost your system’s efficiency and cut down on energy costs, pick a full port ball valve. You will see better flow and less wasted pressure.

Carbon Steel Valve Performance

Leak Prevention

You want your system to be safe and dry. Leaks can cause big trouble in any project. Carbon steel ball valves can leak for a few reasons. Worn packing, broken seats, or bad installation are common causes. You can stop leaks by picking valves with smart designs.

Packing can wear out or get loose. This causes leaks on the outside. You can fix this by tightening or changing the packing.

If the seat is damaged or dirt gets inside, leaks can happen inside the valve. Checking your valve often helps you find these problems early.

Seals can wear out too. You should look at seats, O-rings, and seals often. Change them if they look bad.

If you do not install the valve right, leaks can happen near the stem packing. Always follow the right steps when you put in a 2-way ball valve or a 3-way ball valve.

Here is a table that shows how to stop leaks:

Cause of Leak | Mitigation Strategy |

|---|---|

Use special materials for seals and keep up with maintenance | |

Improper Installation | Follow correct installation steps for every valve |

A 2-way ball valve has a simple flow path. This makes it easy to find and fix leaks. If you want more control, a 3-way ball valve lets you move flow in different ways. Both types help keep your system tight and safe.

API 598 tests every carbon steel ball valve for leaks. For liquid, only 2 drops per minute per inch are allowed. For gas, only 4 bubbles per minute per inch are allowed. These rules make sure your valves work well.

Tip: Always check your valves before and after you put them in. This helps you find leaks early and keeps your system safe.

Safety Features

You need good safety features to protect your stuff and people. The 2 Piece 2000 WOG carbon steel ball valve has many safety designs.

Blow-out proof stem keeps the stem from popping out. It uses nickel-plated brass to make it strong.

Adjustable packing gland lets you tighten the seal if it gets loose. It uses pure PTFE and a strong washer for better use.

Handle lock stops people from turning the valve by mistake. You can lock the handle for more safety.

Limited position design helps you control flow and avoid mistakes.

Here is a table that explains these features:

Feature | Description |

|---|---|

Blowout-proof stem | Nickel-plated brass adds durability |

Adjustable packing gland | Pure PTFE and reinforced washer for easy adjustment |

Maintenance | Lower torque design makes maintenance simple |

A 2-way ball valve is good for simple on-off jobs. If you need to mix or move flow, a 3-way ball valve gives you more choices. Both actuated valves have good safety features. You can pick fire safe certified valves for extra safety in risky places.

API 598 testing shows every valve meets tough safety and leak rules. You can trust your carbon steel ball valve to work in hard jobs.

Note: Safety features like blow-out proof stems and handle locks help stop accidents and keep your system working well.

You can use actuated 2-way and 3-way ball valves in many jobs. These valves work in water treatment, oil and gas, and chemical plants. You get strong and safe performance every time.

Ball Valve Applications

Media Compatibility

You can use a carbon steel valve with many fluids. This makes it a good choice for lots of projects. Here are some things that work well with these valves:

Water, like fresh water, sewage, and sea water

Air and steam

Food and medicine

Chemicals, such as oils, acids, alkalis, and salts

If you use a ball valve with strong chemicals, think about chemical resistance. Carbon steel valves often have special coatings or linings. These help protect the valve from things that can cause rust or damage. This matters if you work with strong acids or bases. Some chemicals, like hydrochloric acid or sulfuric acid, can hurt carbon steel over time. Even weak acids might cause rust if the valve touches them for a long time. Always check if your fluid needs extra protection.

Note: Coatings and linings help your valve last longer in tough places.

Industry Use Cases

You will see these valves in many industries. Each industry needs something different, but carbon steel valves work for most jobs. Here are some common uses:

Industry | Common Applications | Key Requirements |

|---|---|---|

Oil & Gas | Pipeline shutoff, wellheads, refineries | High-pressure capability |

Chemical | Acid, alkali, and salt solutions | Material compatibility, durability |

Power | Steam lines, boiler feedwater, cooling systems | High temperature and pressure |

Water Treatment | Municipal supply, wastewater, desalination | Corrosion resistance, flow control |

Food & Pharma | General-purpose fluid control | Versatility, reliability |

You might use a standard port ball valve for simple flow jobs. A full port design gives you better flow when you need it. In oil and gas, you need valves that can handle high pressure. In water treatment, you want valves that do not rust. Chemical plants need valves that can stand up to harsh fluids. Power plants use these valves for steam and cooling. Food and drug companies use them for safe and steady work.

A ball valve helps you control flow, shut off lines fast, and keep your system safe. You can trust carbon steel for strength and long life in many places.

Cost & Maintenance

Value Over Time

If you pick a carbon steel ball valve, you make a smart choice. This valve can last for many years and helps your system work well. Most people want to know how long the valve will last before it needs to be changed. Here is what you should know:

A carbon steel ball valve can last 10 to 20 years if you take care of it.

In tough places, it might only last 5 years or less.

You should also think about how much money you spend over time. Carbon steel ball valves usually cost less at first and save you money later. The table below shows how they compare to other types over 10 years:

Factor | Carbon Steel Ball Valves | Other Materials |

|---|---|---|

Initial Cost | Lower | Higher |

Durability | High | Varies |

Maintenance Requirements | Moderate | Higher for some materials |

Potential Downtime Costs | Lower due to durability | Higher for less durable materials |

Energy Efficiency | Low torque operation reduces actuator size/cost | Varies |

Tip: Choosing a strong valve helps you avoid repairs and stops your system from breaking down.

Maintenance Ease

You want your equipment to work well without much trouble. Carbon steel valves are easy to take care of. You can follow a simple plan to keep your valve working. Here is a guide for high-pressure jobs:

Interval | Maintenance Tasks |

|---|---|

Monthly | Visual inspection for external leakage, Operation verification, Check for noise |

Quarterly | Lubricate stem, Check packing tightness, Clean surfaces, Verify position indicators |

Annually | Internal inspection, Replace seals, Check ball surface, Lubricate components |

Monthly checks help you find problems early. Lubricating and cleaning every few months keeps the valve working well. Once a year, look inside and change any old parts. This plan helps your ball valve last longer and keeps your system safe.

Note: Taking care of your valve often helps it last longer and saves you money.

You get lots of good things with a carbon steel ball valve. These valves last a long time. They let lots of liquid or gas move fast. You can open and close them quickly. The 2 Piece 2000 WOG Carbon Steel Ball Valve is special. It can handle 2000 PSI. It has a strong TFE seat. It also has safety parts.

The table below shows the main strong points:

Strength | Description |

|---|---|

Durability | Lasts long, needs less fixing |

Safety | Stem won’t pop out, handle locks |

Versatility | Works with many fluids and setups |

Think about using a carbon steel ball valve for your next job.

FAQ

What media can you use with a carbon steel ball valve?

You can use water, air, steam, oil, chemicals, and even food products. Carbon steel ball valves work well with many types of fluids. Always check if your media needs extra protection or coatings.

How do you maintain a carbon steel ball valve?

You should inspect the valve every month. Lubricate the stem and check the packing gland. Clean the surfaces and replace seals once a year. Regular care helps your valve last longer.

What safety features does the 2 Piece 2000 WOG Carbon Steel Ball Valve have?

You get a blow-out proof stem, adjustable packing gland, and a handle lock. These features help prevent accidents and keep your system safe.

Can you use carbon steel ball valves in high-pressure systems?

Yes, you can. The 2 Piece 2000 WOG Carbon Steel Ball Valve handles up to 2000 PSI. This makes it a strong choice for high-pressure jobs.

What sizes are available for carbon steel ball valves?

You can choose sizes from 1/2 inch to 4 inches. Pick the size that fits your piping system best.

评论

发表评论